Mitigating climate change with decarbonisation process

Singapore, 2 July 2020 — Carbon emissions make up 97 per cent of Singapore’s total greenhouse gas emissions. Under the Paris Agreement, Singapore has pledged to, by 2030, reduce its emissions intensity by 36 per cent from 2005 levels, and to stabilise its emissions and peak around 2030. The Singapore government has announced its long-term strategy to halve emissions from its 2030 peak and achieve net-zero emissions as soon as viable.

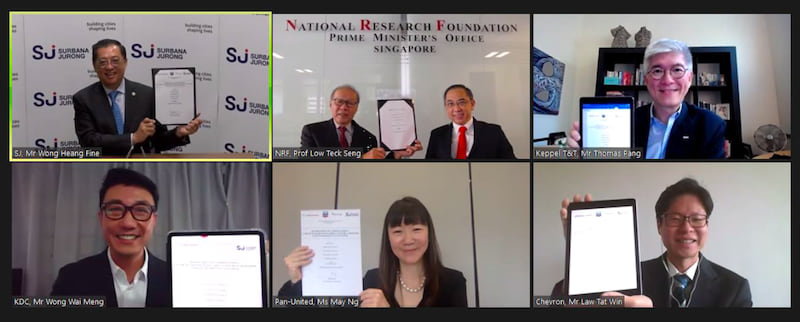

With the support of the National Research Foundation, Keppel Data Centres, Chevron, Pan-United and Surbana Jurong signed a Memorandum of Understanding (MOU) today, committing to harness their combined resources and jointly develop the first end-to-end decarbonisation process in Singapore. This collaboration is aimed at accelerating the development of a highly integrated clean and energy-efficient Carbon Capture, Utilisation & Sequestration (CCUS) system that can lead to a low-carbon economy and potential commercial developments for Singapore.

To this end, the partnership will develop CCUS technologies that are readily applicable, with high technical readiness and cost efficiency to implement in Singapore’s key industries such as energy, chemicals and construction.

When commercially viable, the CCUS technologies are expected to help reduce carbon intensity across the industry sectors and help Singapore halve emissions from its peak to 33MtCO2e by 2050, with a view to achieving net-zero emissions as soon as viable in the second half of the century.

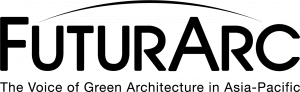

Carbon utilisation is the last stage of the CCUS system. There are three tracks that will be explored:

Low-carbon concrete: This concrete with a much reduced carbon footprint is achieved by maximising the use of ground granulated blast furnace slag or GGBFS (a cementitious by-product of steel production) to replace ordinary Portland cement, which has high carbon emissions. In addition, natural aggregates are replaced by recycled concrete aggregates and washed copper slag. Carbon dioxide is injected into the concrete mix, converting the carbon dioxide into a mineral that increases the concrete strength, enabling less cement to be used. The final product is a low carbon concrete that has a carbon footprint approximately 46 per cent lower than normal concrete.

Mineralisation: Carbon sequestration in construction materials (cement, sand, aggregates, etc.) can be achieved through the introduction of carbonates. One of the primary objectives of concrete sustainability innovation is to increase the carbon dioxide (CO2) sequestration in such materials and consequently enable it to still meet construction industry standards.

Methanol: Green methanol production, i.e., methanol synthesised via direct CO2 hydrogenation or via syngas hydrogenation after the reverse water-gas-shift reaction, rather than from methane reforming, can be a highly attractive CCU pathway for a future low-carbon economy.

Second row: CEO of Keppel Data Centres, Wong Wai Meng; CEO of Pan-United Corporation, May Ng; Chairman, Chevron Singapore Country Office, Law Tat Win.